GOVERNMENT

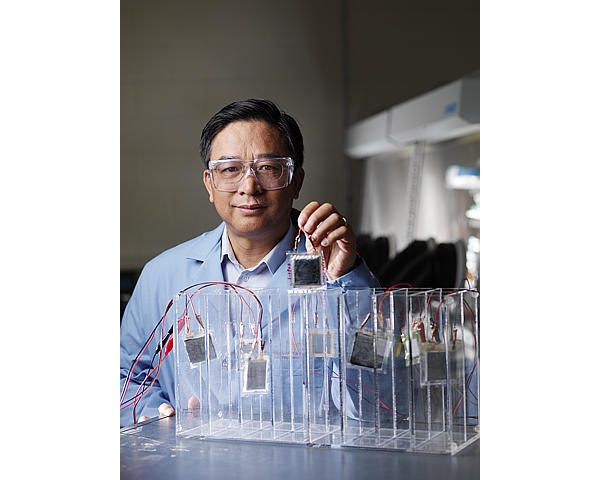

Zhang performs MD simulations for next-generation batteries

Dendrites — the microscopic, pin-like fibers that cause rechargeable batteries to short circuit — create fire hazards and can limit the ability of batteries to power our smart phones and store renewable energy for a rainy day.

Now a new electrolyte for lithium batteries that's described in Nature Communications eliminates dendrites while also enabling batteries to be highly efficient and carry a large amount of electric current. Batteries using other dendrite-limiting solutions haven't been able to maintain both high efficiencies and current densities.

"Our new electrolyte helps lithium batteries be more than 99 percent efficient and enables them to carry more than ten times more electric current per area than previous technologies," said physicist Ji-Guang "Jason" Zhang of the Department of Energy's Pacific Northwest National Laboratory. "This new discovery could kick-start the development of powerful and practical next-generation rechargeable batteries such as lithium-sulfur, lithium-air and lithium-metal batteries."

Battery 101

Most of the rechargeable batteries used today are lithium-ion batteries, which have two electrodes: one that's positively charged and contains lithium and another, negative one that's typically made of graphite. Electricity is generated when electrons flow through a wire that connects the two. To control the electrons, positively charged lithium atoms shuffle from one electrode to the other through another path: the electrolyte solution in which the electrodes sit. But graphite has a low energy storage capacity, limiting the amount of energy a lithium-ion battery can provide smart phones and electric vehicles.

When lithium-based rechargeable batteries were first developed in the 1970s, researchers used lithium for the negative electrode, which is also known as an anode. Lithium was chosen because it has ten times more energy storage capacity than graphite. Problem was, the lithium-carrying electrolyte reacted with the lithium anode. This caused microscopic lithium dendrites to grow and led the early batteries to fail.

Many have tweaked rechargeable batteries over the years in an attempt to resolve the dendrite problem. In the early 1990s, researchers switched to other materials such as graphite for the anode. More recently, scientists have also coated the anode with a protective layer, while others have created electrolyte additives. Some solutions eliminated dendrites, but also resulted in impractical batteries with little power. Other methods only slowed, but didn't stop, the fiber's growth.

Concentrated secret sauce

Thinking today's rechargeable lithium-ion batteries with graphite anodes could be near their peak energy capacity, PNNL is taking another look at the older designs. Zhang and his team sought to develop an electrolyte that worked well in batteries with a high-capacity lithium anode. They noted others had some success with electrolytes with high salt concentrations and decided to use large amounts of the lithium bis(fluorosulfonyl)imide salt they were considering. To make the electrolyte, they added the salt to a solvent called dimethoxyethane.

The researchers built a circular test cell that was slightly smaller than a quarter. The cell used the new electrolyte and a lithium anode. Instead of growing dendrites, the anode developed a thin, relatively smooth layer of lithium nodules that didn't short-circuit the battery.

After 1,000 repeated charge and discharge cycles, the test cell retained a remarkable 98.4 percent of its initial energy while carrying 4 milliAmps of electrical current per square centimeter of area. They found greater current densities resulted in slightly lower efficiencies. For example, a current density as high as 10 milliAmps per square centimeter, the test cell maintained an efficiency of more than 97 percent. And a test cell carrying just 0.2 milliAmps per square centimeter achieved a whopping 99.1 percent efficiency. Most batteries with lithium anodes operate at a current density of 1 milliAmps per square centimeter or less and fail after less than 300 cycles.

Anode-free battery?

The new electrolyte's remarkably high efficiency could also open the door for an anode-free battery, Zhang noted. The negative electrodes in today's batteries actually consist of thin pieces of metal such as copper that are coated in active materials such as graphite or lithium. The thin metal bases are called current collectors, as they are what keep electrons flowing to power our cell phones. Active materials have been needed to coat the electrodes because, so far, most electrolytes have been inefficient and continue to consume lithium ions during battery operation. But an electrolyte with more than 99 percent efficiency means there's potential to create a battery that only has a negative current collector, without an active material coating, on the anode side.

"Not needing an anode could lower the cost and size of rechargeable batteries and would also significantly improve the safety of these batteries," Zhang said.

The electrolyte needs to be refined before it's ready for mainstream use, however. Zhang and his colleagues are evaluating various additives to further enhance their electrolyte so a lithium battery using it could achieve more than 99.9 percent efficiency, a level that's needed for commercial adoption. They are also examining which cathode materials would work best in combination with their new electrolyte.

To analyze battery material performance, the researchers used advanced techniques such as a scanning electron microscopy and X-ray photoelectron spectroscopy at EMSL, the Environmental Molecular Sciences Laboratory, a DOE Office of Science national user facility at PNNL. They also performed molecular dynamic simulations with the help of the Army Research Laboratory. Funding for the project was provided by the Joint Center for Energy Storage Research through DOE's Office of Science.