INDUSTRY

FloTHERM XT leads innovation in electronics cooling

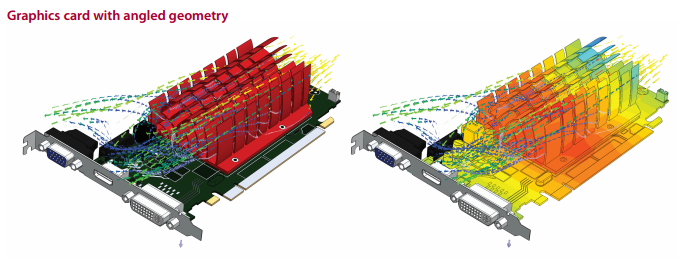

Mentor Graphics has announced the newest version of the FloTHERM XT software product with advanced thermal management capabilities for electronic systems, printed circuit board (PCB) and packages of any geometric complexity. As the industry's first integrated mechanical design automation (MDA) and electronic design automation (EDA) electronics cooling solution, the FloTHERM XT product has CAD-centric technology and a robust mesher which simulates complex geometries with ease, speed, and accuracy.

The new FloTHERM XT product now supports transient analysis, Joule heating, parametric studies, extended EDA integration capabilities, and new modeling options, including a cutting-edge ability to represent copper in detail for complex PCBs. These capabilities provide an ideal solution for the thermal simulation of electronic devices used in a broad range of markets including automotive, transportation, consumer electronics, industrial automation as well as aerospace and defense.

"FloTHERM XT extended modeling, EDA interfacing capabilities and UI improvements have been well received by our customers as well as our consulting team," said William Maltz, president and founder, Electronic Cooling Solutions Inc. "We can now take raw mechanical and electrical design data for an electronics system through to a viable thermal model appropriate for advanced parametric analysis. The improvements offered by FloTHERM XT enable us to work more efficiently and to build and run models with a significant reduction of engineering time and effort."

For thermal specialists and design engineers, the FloTHERM XT product provides early design virtual prototyping and advanced "what-if" analysis for improved product quality, minimized design iterations, and faster time to market. New key product capabilities include:

-- Transient Analysis: time-varying analyses across all industrial

applications is enabled with the FloTHERM XT state-of-the-art solver and

intuitive user interface (UI).

-- Component and Board Manipulation: time is saved by importing any board

and component layout and easily modifying data for position, size,

orientation, shape and modeling level prior to transfer to the FloTHERM

XT product.

-- Joule Heating: comprehensive analysis platform predicts current density,

electric potential, and associated Joule heating effects in complex

electronics systems, PCBs and other high-power devices - a valuable

feature for automotive and power electronics applications.

-- Parametric Study: a new integrated environment for defining, solving and

analyzing results for parametric variations of geometry, attributes

(e.g. material, thermal) plus solution parameters significantly enhances

the design optimization process.

-- EDA Tool Connectivity: a new ODB++ interface for non-Mentor Graphics

layout tools supports Cadence, Zuken and Altium and helps users save

time by providing increased user flexibility and use of existing EDA

data.

-- New Modeling Options: PCB copper nets and traces are represented in full

3D detail, critical for higher-fidelity solutions or high-power

applications using Joule heating effects for critical devices on a

board.

-- Enhanced UI: easy-to-use interface and enhanced functionality enables

efficient use of the FloTHERM XT software for an improved intuitive user

experience.

"We continually strive to make our advanced technologies easier to use, yet more powerful, for our customers - and our new FloTHERM XT product continues to deliver on this promise," stated Roland Feldhinkel, general manager of Mentor Graphics Mechanical Analysis Division. "This version enables optimum productivity for today's engineers by providing the needed power, performance and advanced capabilities including EDA support to handle the most complex geometries inside an easy-to-use environment."

The new FloTHERM XT product is available for immediate shipment. Additional product information can be found on the company website: http://www.mentor.com/products/mechanical/flotherm/flotherm-xt/